materials

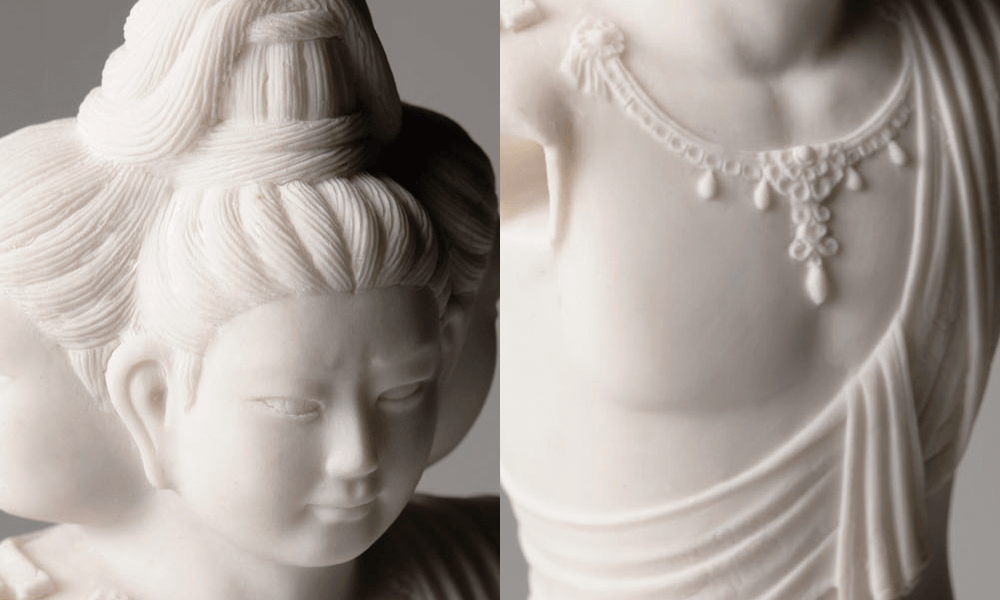

Pursuit of materials is another area that isumu is committed to. Our Buddhist statues are made of polystone, which is a mixture of stone powder and synthetic resin.

The method is called “cold cast” because the curing of the mold is done in room temperature. Polystone is an ultimate material in that it has a significant weight and an incredible ability to capture the minute details.

The composition of stone powder and resin is varied depending on the temperature and humidity of the environment, as well as the nature of the part to be used to achieve perfection and durability.

manufacturing

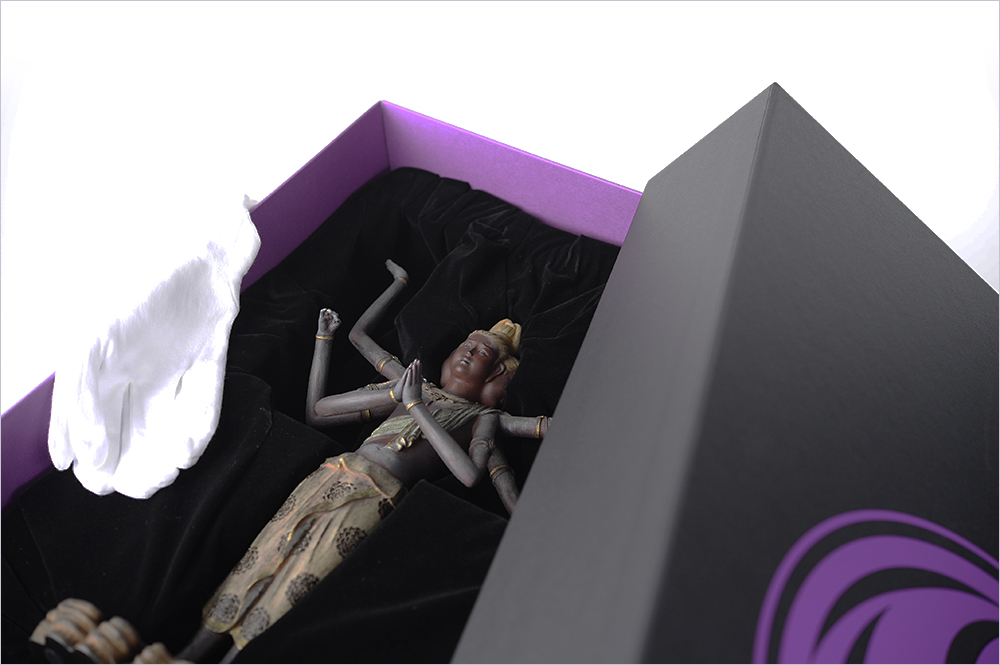

Prototype production is the first step to determine the overall quality of the product. Professional staff working exclusively for isumu put their whole heart into producing the prototypes to reproduce the delicate beauty of the statues. They spend nearly two months to finish the prototypes for a single figure. Their focus is always placed on the facial expression. Even a slight difference in the size of the eyeballs makes a big difference. The artisans go through a process of trial and error based on elaborate calculations and experience until they achieve satisfying results. The deep understanding of Buddist statues and high aspirations make isumu unique in creating “Authentic” reproduction.

Silicone molds are used instead of metallic molds since the former material is suitable for expressing delicate forms. Yet the softness of silicone requires care and skills in handling such as in making a silicone mold out of a clay mold. Moreover, unlike metallic molds, silicone molds only last for producing a few dozens of products. It is more of handwork and far from what you would call mass production. The more complicated the form of the statue is, the larger number of parts is required. Each and every part is formed with elaborate care.

Polishing is also an indispensable process in manufacturing our products. Parts extracted from the molds cannot be used as they are. They have to go through a series of polishing stages before they are ready to be assembled. Time and labor invested in careful polishing of each part determine the quality of the finished products. Fine air bubbles and blemishes are removed to finish the products in perfect condition.

Coloring is the most laborious process of all, commanding many kinds of colors including acrylic pigment, clear oil, gold leaf to reproduce the statue’s history of over 1,000 years. Above all, coloring of the eyes affects the total finish of the statue. Only one out of the artisans at isumu is skilled enough to execute the difficult task. It is truly “a sacred area” in the entire production process.

honesty and sincerity

Pursuit of materials is another area that isumu is committed to. Our Buddhist statues are made of polystone, which is a mixture of stone powder and synthetic resin.

The method is called “cold cast” because the curing of the mold is done in room temperature. Polystone is an ultimate material in that it has a significant weight and an incredible ability to capture the minute details.

The composition of stone powder and resin is varied depending on the temperature and humidity of the environment, as well as the nature of the part to be used to achieve perfection and durability.

maintenance

Pursuit of materials is another area that isumu is committed to. Our Buddhist statues are made of polystone, which is a mixture of stone powder and synthetic resin.

The method is called “cold cast” because the curing of the mold is done in room temperature. Polystone is an ultimate material in that it has a significant weight and an incredible ability to capture the minute details.

The composition of stone powder and resin is varied depending on the temperature and humidity of the environment, as well as the nature of the part to be used to achieve perfection and durability.